|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

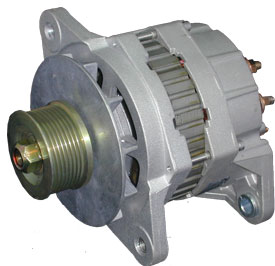

High output marine alternators so powerful that you can weld with them!The ZENA® mobile welding system is a new technology, self-contained, ultra-compact, commercial duty, engine-driven DC welder which can be attached to any engine. This welding system uses a unique, modular, electrically isolated DC welding power generator, which is built by ZENA, Incorporated, in the USA, to withstand the extraordinary stresses of high current welding in severe operating environments. But, that's not all!While it's definitely NOT a standard alternator, in addition to generating DC welding current, a ZENA® DC power generator can also be used to: replace a standard marine alternator in diesel powered vessels, or toreplace (or be used as) a secondary alternator dedicated to charging/maintaining secondary battery banks, or tofunction as a part of a multi-generator high output, heavy duty, high current battery charging system, oras an onboard DC power source for large non standard electrical loads such as exotic sound systems, communication systems, or computer systems, oras the key component in an ultra-compact custom DC genset applicationZENA alternators/power generators are designed for external regulation -- and are designed to be completely compatible with ALL types and brands of heavy duty (8-10A rotor current) external voltage regulators! This means that you can take advantage of a wide range of alternator control systems ranging from simple, automotive voltage regulators to the most sophisticated multistage and/or programmable voltage regulator units/systems on the market -- including the line of highly specialized and sophisticated regulators that we have designed to take maximum advantage of all of the capabilities and features built into our ZENA power generators! And, it also means that you can probably replace your existing alternator with a ZENA unit without the expense of replacing your existing external regulator! Need very high charging current?ZENA power generators/alternators are also designed to work as secondary alternators dedicated to charging a large secondary battery bank -- or supplying power for other nonstandard electrical loads. Used in this way, your engine starting battery and stock alternator can be left in place -- operating as they were designed to do -- insuring the integrity of key operating/safety systems. Read about choosing a high current alternator, then take your choice from:a 150 amp @ 13-22 VDC welding power generator/high-amp alternator (model SR150.12 -- our most popular model); ora 200 amp @ 13-22 VDC welding power generator/high-output alternator (model SR200.12); ora 250 amp @ 13-22 VDC welding power generator/high-output alternator (model SR250.12); ora 80 amp @ 24-36 VDC high-amp alternator (model SR150.24); ora 125 amp @ 24-36 VDC high-output alternator (model SR200.24); ora 140 amp @ 24-36 VDC high-output alternator (model SR250.24)

Need even more power / charging current?Thanks to unique construction features and our unique electronic control system, multiple power generating units/alternators can be attached to the same engine, or multiple engines -- controlled and used together -- just as if the individual generators were a single giant alternator! Specifically designed for use in this manner, with the appropriate control accessories, ZENA's modular power generators/alternators can be used in synchronized groups to efficiently produce very high, well regulated battery charging currents -- from 150 to over 1,200 amps., in 12 volt systems -- and over 750 amps in 24 volt applications! The use of multiple generators on a given engine, strategically mounted (for example on opposite sides of an engine) can also serve to remove side loading stress from engine bearings while still allowing the installation of a large charging system. Typical charging/DC generating systems include: a 300 amp* @ 13-22 VDC multiple alternator generating system;a 400 amp* @ 13-22 VDC multiple alternator generating system;a 500 amp* @ 13-22 VDC multiple alternator generating system;a 600 amp* @ 13-22 VDC multiple alternator generating system;a 800 amp* @ 13-22 VDC multiple alternator generating system;a 1000 amp* @ 13-22 VDC multiple alternator generating system; orlarger charging systems can easily be configured!

Unique Design Features Provide Unique Performance BenefitsThe typical alternator is just not built like a ZENA DC power generator (a key reason why we make this distinction rather than referring to them simply as alternators). Therefore, if quickly charging batteries is important, a ZENA power generator is an ideal solution. Unlike standard high-amp alternators most of which are designed to produce high currents for a relatively brief period, a ZENA power generator/alternator has been built to produce higher currents continuously --- an absolute necessity for welding, and also a great feature for big charging jobs. A number of features make ZENA power generators different from standard high current marine alternators: ZENA power generators are designed so that they can be controlled with either A or B Circuit (type N or type P) external voltage regulators, or with ZENA's model WC.VR voltage regulator and WC.12 or WC.24 multi-generator controls.Ultra heavy duty output terminals are fabricated from silicon bronze (almost pure copper, but more durable) to insure minimal corrosion in marine environments as well as minimal electrical resistance to the huge charging currents that ZENA power generators can produce (many alternators use high resistance, easily corroded, mild steel terminals on their alternators). AND, these oversize bronze terminals are no less than 5/16" in diameter at any point -- capable of easily handling much larger charging currents -- unlike many so-called high-amp/heavy-duty alternators which only appear to have heavy duty output terminals while internal current handling components are actually far smaller.Generator/alternator output is completely isolated electrically from the generator/alternator case (and, therefore, from the vessel's ground plane). When connected to take advantage of this feature, high amp alternator charging currents can flow directly to the batteries WITHOUT having to also pass through hull or fittings. This feature also makes connection of generators in series parallel combinations possible.Generator/alternator field circuits are also completely isolated electrically from the generator/alternator case (and, therefore, from the vessel's ground plane) enabling special regulation systems to be implemented without modification.Rectifiers in all ZENA power generators/alternators are more than double the size required to handle rated output currents, and are also capable of handling exceptionally high reverse voltage spikes. Rectifier heat sinks are equally robust allowing reliable high amp operation in exceptionally hot operating environments.

|

||||||||||||||||||||||||||||||||||||||

|

® ZENA is a registered trademark owned by ZENA, Inc. for its welding systems and related products.

US & Foreign Patents Pending © Copyright 2000-2018 by ZENA, Incorporated. All rights reserved. |

||||||||||||||||||||||||||||||||||||||