| The pictures on this page detail key aspects of a ZENA welder installation into a 3/4 ton Chevrolet service truck with a V-8 engine. |

|

| In this case, the truck had a serpentine drive belt system, necessitating the use of a ZENA Add-A-Pulley™ retrofittable secondary pulley assembly. This accessory eliminates the need to make any changes to the stock drive belt system. |

|

|

Add-A-Pulley™ attached to existing alternator. |

|

|

|

|

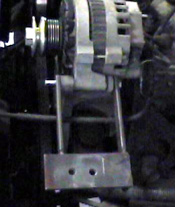

Site fabricated bracket is used with ZENA A300 universal mounting bracket to mount Power Generator

|

A 1-1/4” strap us used below the bracket assembly (attached with a 5/16” bolt) to further secure and solidly fix the position of the bracket assembly. |

|

Ready for fabrication of tensioning bracket |

|

|

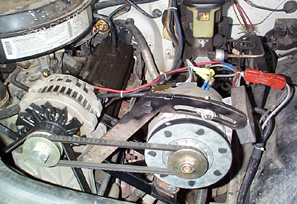

A modified A215 bracket is used to secure the unit's position and to tighten the drive belt. Belt length was selected so that the Power Generator's drive belt tension is adjusted by pulling out and down on the Power Generator |

|

Everything together & ready to weld |

|

| This vehicle is used for frequent welding jobs and was also equipped with an ASC1 automatic engine speed control accessory and a BJ150.4 lead extension kit which is used to make it easy for workers to attach and remove welding and control cables. |

|

|

ASC1 Automatic Speed Control |

Time to install from scratch - approximately 4 hours (including time to design installation, bore and tap holes, buy materials and fan belt, and bracket fabrication).

| Go to Web Site Map | Go to Top of Page |

US & Foreign Patents Pending

© Copyright 1998,1999 by ZENA, Incorporated. All rights reserved.

[an error occurred while processing this directive]