| Working

daily on a farm, this mobile 150 amp., 100% duty cycle riding welder goes anywhere

one can walk --- a most useful (and very frequently used) piece of maintenance equipment. To quote the owner, I don't know how we ever made do without it --- paid for itself in the first month. This installation is particularly interesting in that it illustrates a number of techniques that are typical to many ZENA welding system installations. |

|

|

|

|

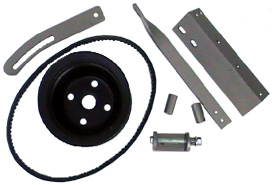

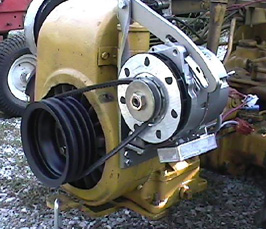

| These

views show the installation components (including completed mounting bracket assembly). ZENA A300 and A215 Brackets were used. The V-belt is from an auto parts store, the large pulley comes from a Chevrolet dealer, and the other components were fabricated on site using 1x1/4 bar stock, 2x1/4 angle stock, and 1/4 wall tubing/pipe (for spacers). Misc. nuts and bolts were also utilized. |

|

|

|

|

|

|

| The Power Generator is mounted to the tractor using a simple bracket assembly which is made by using a ZENA A300 universal mounting bracket which is mounted (using 5/16 bolts) to a piece of 2x1/4 angle stock. The 2 angle is mounted to the engine via existing bolt holes which are used to mount the engine's starter motor. Longer bolts are selected and spacers are used to space the 2 angle away from the engine just enough to clear the starter motor and surrounding components. A tensioning arm is made up from a piece of 1-1/4x1/4 bar stock (twisted 90° - see photos), and a shortened ZENA A215 slotted tension arm bracket. The tensioning arm components are assembled and the arm is attached to the 2 angle using 5/16 bolts. |

|

|

|

|

|

|

|

|

| Go to Web Site Map | Go to Top of Page |

US & Foreign Patents Pending

© Copyright 1998,1999 by ZENA, Incorporated. All rights reserved.

[an error occurred while processing this directive]