|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| USE LANDSCAPE VIEW WHEN VIEWING WITH MOBILE DEVICES |

The

|

CLICK ON ANY PICTURE OR UNDERLINED LINKS FOR MORE INFORMATION |

||

|

||||

The patented ZENA® mobile welding system is designed and manufactured in the USA by ZENA, Incorporated.

Unique ZENA® welding systems are:

Welcome to go

|

||

MORE VIDEOS |

the Most Technically Advanced,

the Most Reliable,

the Most Compact,

the Most Efficient,

the Most Unique,

the Most Versatile,

the Safest, and

the Easiest to Use

OEM and/or retrofittable commercial-duty, engine-driven, 100% duty cycle, multi-process, DC arc welders in the world!

And, thanks to fingertip remote controls that let you adjust power even WHILE you're welding, you'll enjoy far more control of the welding process than you've ever had with any other welder!

A ZENA® mobile DC welder can be attached to the engine of ANY existing vehicle (saving the cost of a separate/new engine).

|

|

ZENA SR200 200 amp, 100% duty

|

|

This unique portable welder is equally at home on:

a service truck -- using a ZENA underhood welder -- performing urban industrial maintenance; or on

a farm truck or tractor -- using a ZENA onboard welder to fix a damaged piece of farm equipment in a remote field; or on

a front end loader, man lift, skid loader, or bull dozier working in a quarry, mine, or construction site; or on

a military support or combat vehicle -- repairing a broken frame member or other damage that's keeping the vehicle out of action; on on

an emergency vehicle working at a disaster site; or on

a well drilling rig -- driven by the rig's engine welding casing and making site repairs as needed; or on

a line shaft-- in a factory where electrical power for welding is not available; or on

an ocean going yacht, offshore cruiser, or work boat -- making repairs in the middle of an ocean or foreign port; or on

a 4x4 off-road vehicle -- in need of repairs when operating far from assistance-- at a remote desert, mountain, or jungle site!

You no longer need a huge engine driven welding machine taking up most of the space in a pickup truck bed (and most of the payload as well) to do commercial welding. ZENA's new technology replaces these out dated behemoths with an underhood generator package so small, and so light, that there is: NO practical reduction in vehicle payload -- and NO loss of cargo space! Though, you will notice a huge reduction in your welding equipment cost!

ZENA DC welders can be retrofitted to existing freestanding motors of all kinds including electric motors, hydraulic motors -- even pneumatic motors.

Install a ZENA underhood welder and your vehicle becomes an:

all weather, go anywhere, commercial duty, mobile welding station that

out performs ALL other top-quality high current engine powered welders, and

does this without ANY reduction in vehicle payload!

Attach or retrofit a ZENA welder to a free standing engine and you can have the ultimate portable welder:

build your own engine driven portable welder (do it yourself installation is well within the capabilities of the typical do-it-yourselfer), OR

rebuild a worn out engine driven welder, OR even

make yourself a riding welder!

Installation is simple -- designed for do-it-yourselfers. ALL Parts are modular, wires are color coded, and everything plugs together easily. We even have factory made bolt in bracket kits for most of the American trucks made during the last 20 years!

Best of all, when you're done, you'll have a brand new commercial duty ZENA welder -- for far less than a worn out used portable welder!

That's right, LESS than the cost of a piece-of-junk welder selling at auction!And, from one-half to one-fifth the cost of a comparable new engine driven welder!

Don't want to build your own?

Factory installed ZENA welders are available!

Our ZENA® hydraulic drive welders are perfect for use on service trucks and lift trucks with hydraulic power and absolutely perfect for use on drilling rigs, and man lifts -- including scissor lifts, boom lifts, basket lifts, cranes, etc.

Forget about having to equip your truck, lift, or drilling rig with expensive, space wasting, heavy engine driven welders, long cables, loss of lift capacity -- or needing a helper just to adjust power and move the welder around the lift's work area.

Specifically designed for the rigors of rental and long term construction site duty -- in all weather conditions. In addition to incredible ZENA welder performance, ZENA's unique hydraulically driven welders offer the ultimate in reliability, ease of retrofit and serviceability. In fact these hydraulic drive welding units require no routine maintenance of any kind!

Best of all, you don't have to purchase a new lift to get an onboard welder! Your existing equipment can be easily converted in your service shop by your own maintenance personnel!

We have a number of dealers and/or distributors, in the US and Europe who built high quality turnkey, ready-to-go, light weight gas and diesel engine driven multi-process ZENA welders -- even combination service truck workstations providing high amp DC welding current for stick, MIG, and TIG welding; AC power for tools; high current DC battery charging/boosting power; and compressed air!Call us for more information on these resources -- and check our LINKS page for details on some of these providers (not a complete list).

Making Conventional Engine Driven Welders Obsolete --

A Disruptive Technology

ZENA's patented welding power generation and control technology is a sea change -- a true "disruptive technology" in an industry heretofore dominated by a few big firms who have maintained engine driven welder technology with little, or no, real innovative improvement for more than 50 years.

For example, in addition to being relatively inexpensive to manufacture (with NO need to sacrifice quality to make them affordable), ZENA's welders are incredibly compact when compared to previous technology. Yet they are able to produce far more welding power than old fashioned, engine driven welders more than 5 to 20 times their weight! Better still, these tiny powerhouses produce remarkably little waste heat and ALL electronic components are MODULAR and COMPLETELY WATERPROOF -- sealed in a high tech plastic. And, since heat and moisture are the main enemy of all electronic products, less heat and/or moisture = longer service life (and fewer problems)!

Put another way, these tiny ZENA welders will work productively, and more reliably, for much, much longer than old technology engine driven welders. This is not just rhetoric Check out our warranty -- 3 full years -- as long, or longer, than that provided for ANY welders made anywhere in the world. When have your ever seen a welder sold with a 60 day satisfaction guarantee?

And, thanks to built-in troubleshooting features and modular components, there is no need to ever take a user serviceable ZENA welder in to a service facility -- and pay a huge fee just to see if there was anything wrong in the first place. Just follow a simple troubleshooting procedure, observe the action of a few lights, make a simple resistance or voltage reading and you're done.

Small size has many other benefits:

Easier installation,

lower manufacturing and shipping costs,

virtually no loss of vehicle payload capacity,

improved vehicle fuel efficiency (less air pollution, etc.)

Equally unique, ZENA's patented electronic controls add a host of features and capabilities that set the ZENA welders far apart from today's host of existing technology based engine driven welders.

See below, OR CLICK HERE FOR MORE INFORMATION.

|

||

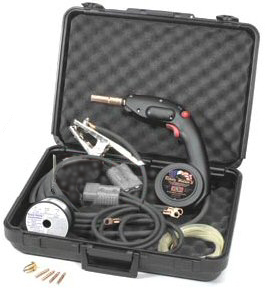

Use a Spool Gun or Spool Feeder with your welder |

||

Last, but far from least, ZENA's new technology welders weld better, and are easier to use, than other engine driven welders:

We're not talking about subtle differences either -- you will notice

much better penetration for a given current setting;

better arc characteristics;

cleaner, x-ray quality joints;

easier out of position welding;

better out of position weld joints; and

unprecedented user control of the welding process.

Choose the 100% duty cycle welder that meets your needs

Our unique modular power generating technology and electronic controls let you mount multiple independently controlled 150, 200, 250 Amp 100% duty cycle welders to a single engine --- or combine and synchronize multiple welding power generators to create a single giant power generator producing 800 amps (or more) of welding power.

And, with accessories, your welder can also function as: (more on accessories and models below)